DB25 #8 -- down on the farm

The DB-25 is a good connector in kind of the same way that lap belts were a good safety system. Better than nothing, but enough to make you bang your head on the dashboard sometimes. No great surprise then that many of the cables with a DB-25 on one end exist solely to bridge the gap to a system with a better connector on the other end.

So it is with our 8th entry in the series – The Case / New Holland DPA5 Electronic Service Tool Protocol Adapter and cable. The protocol adapter itself is probably unremarkable. USB to a PC on one end, and a cable to the farm implement on the other. The visible LEDs offer status on "CAN1", "CAN2", and "KLINE". It's a reasonable bet that protocols on offer are not wholly different from OBD systems in automobiles.

Pull the thread on the beefy connector at the other end and you find that it's a standard SAE J1939 connector, used for engine and vehicle diagnostics in heavy-duty vehicles. It's electrically similar enough to automotive OBD-II that adapters exist from one to the other (for use with interfaces that understand nuances in both systems).

How do we wind up going from a waterproof, heavy-duty twist-lock connector to our humble DB-25? Three reasons. First, the DB-25 is smaller. That lets the enclosure be smaller, lets the plastic briefcase for the enclosure be smaller, lets the cardboard box for plastic briefcase for the enclosure be smaller, and lets more get packed onto a ship in a steel intermodal container, all of which make it cheaper to buy and to ship. Second, the connector itself is cheaper. I can't find a J1939 connector available for less than five dollars, while I can buy DB-25 connectors all day long for under seventy-five cents. Third, the DB-25 is available in a variety of configurations that directly mount to a printed circuit board for easy assembly.

Manufacturability matters, but it's fickle. Things are not manufacturable pretty much right up to the moment they are – and remain so until the moment they aren't again. Consider the humble paper cup.

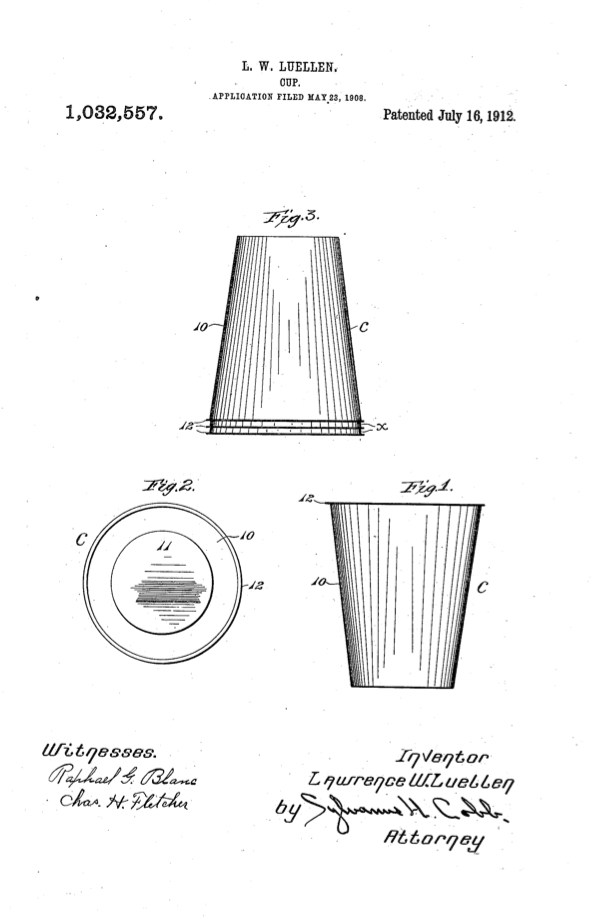

Here's a patent drawing from a paper cup patent application filed in 1908. Though one of many such patents and designs, this is the one that became the Dixie cup.

Not much has changed. You could probably assemble one of these in your kitchen. You could probably even start an Etsy business in artisanal hand-made paper cups (be right back). What's left out of the patent application is that the inventor has invented a machine to make these so quickly and cheaply that the invention makes sense at all.

The invention isn't really the shape described in the patent – The shape and construction of the cup are almost identical to tin cups made since the start of the tinplate industry, and made in America since the 18th century. Here's a modern archeological reconstruction of an early tin cup made in a similar pattern. The author reports about an hour to make a single cup.

Paper cups remain as manufacturable as they ever were, even meta-manufacturable so long as factories exist to make paper-cup-making machines. You can buy a factory-direct paper-cup machine today from China for around $25k (minus tariffs).

Consider now Polaroid film packs – another invention that makes little sense without the machinery that makes it manufacturable. Polaroid film was ubiquitous in the US in the 1970s and 80s. I could get film for my 1976 Sx-70 camera until Polaroid discontinued it in 2006, five years after their original bankruptcy. 30 years of support is a lot more than anyone has yet delivered for smartphone software updates. Manufacturable until it wasn't. But then manufacturable again.

The Impossible Project (now itself called Polaroid) started production of Polaroid-compatible film in 2010. This would have been stupendously uneconomical had they not started with Polaroid's own factory and machinery, purchased at bankruptcy. The new Polaroid later introduced a range of new compatible cameras. These were easy – one piece of modern consumer electronics is essentially the same as another.

In a hundred years, it may be a hobby project to build something as primitive as a picoliter-precise ink-jet printer head from our era. It could be altogether more difficult to come up with a suitable piece of 8x11 copy paper if that technology disappears. I can't yet guess when the DB-25 connector will disappear – probably after the last, last piece of Polaroid film and before the last paper cup. Perhaps not before we see a single-use electronic connector made from paper farmed with a CASE CX130C L Forestry Crawler Excavator, diagnosed through a DB-25.

Member discussion